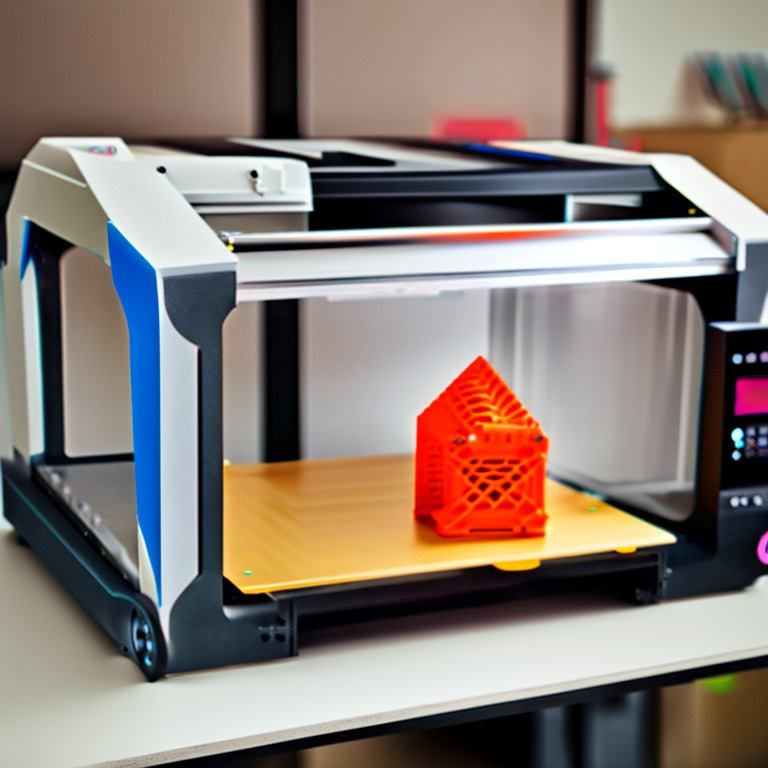

10 Best uses for 3D printers

10 Best uses for 3D printers

As a huge fan of 3D printing, I’ve compiled a list of the 10 best uses for 3D printers. From creating cool gadgets to solving everyday problems, 3D printers have revolutionized the way we think about manufacturing and design.

Customized Jewelry and Accessories

One of the amazing uses of 3D printers is creating customized jewelry and accessories. Whether you want a unique piece to match your outfit or a personalized gift for someone special, 3D printers make it possible to design and create intricate designs that were previously impossible to produce. With 3D printing, the possibilities are endless – from bracelets to earrings, pendants to necklaces, and even customized phone cases! The process is easy and affordable, making it accessible for everyone who wants to add some personalized style to their wardrobe.

Prototype and Product Development

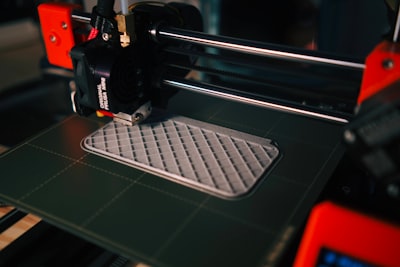

Another great use for 3D printers is in the field of prototype and product development. With the ability to produce physical models quickly and cost-effectively, 3D printing has become an indispensable tool for engineers, designers, and manufacturers. Rapid prototyping allows for faster iterations and testing, resulting in better products that can be brought to market more quickly. This has opened up opportunities for small businesses and startups to compete with larger companies in the product development space.

Replacement Parts Printing

3D printers have also become a lifesaver for people who need replacement parts for machines and appliances. Instead of waiting weeks or even months for the manufacturer to send a replacement part, 3D printing allows you to create the part yourself within hours. This is especially handy for older or hard-to-find parts, as well as for customizing parts to fit specific needs or preferences. From car parts to household appliances, 3D printers have made it easier and more affordable to keep devices functioning smoothly.

Educational Tools and Devices

In addition to the practical uses of 3D printers, they have also become valuable educational tools. With 3D printing, students can create and print their own designs, allowing for a more hands-on and interactive learning experience. This technology has been used to teach everything from biology by creating 3D models of cells and organisms to geometry by allowing students to print and examine their own geometric shapes. The use of 3D printing in education not only makes learning fun but also promotes creativity and innovation among students.

Medical Applications and Implants

Another amazing use for 3D printers is in the medical devices field. Surgeons can create customized implants and prosthetics that are perfectly suited to a patient’s unique anatomy, leading to better outcomes and fewer complications. Plus, 3D printing is being used to create models of organs and tissues for preoperative planning.

Fashion and Cosplay Parts

3D printing has also made its way into the fashion industry. Designers are using 3D printers to create unique and intricate pieces that would be impossible to make by hand. From avant-garde dresses to futuristic shoes, the possibilities are in the realm of science fiction.

Cosplayers are using 3D printers to create intricate costumes and props that perfectly match their favorite characters. With the ability to print in different materials and colors, the possibilities for creating amazing cosplay outfits are endless. Plus, printing out components at home saves on cost compared to buying pre-made pieces.

Home Decor

Looking to add a touch of personality to your home decor? 3D printing can help you create unique fixtures and personalized pieces, from vases to lampshades. You can also print out customized picture frames and wall art to truly make your space your own. The possibilities are endless!

Using easy to use cad (Computer-aided design) software any hobbyists can turn dollars into startups. Just make sure to use high-quality resin or printing materials.

Better Prosthetics

3D printers have revolutionized the field of prosthetics, making it easier and more affordable to build better prosthetics. With 3D printing technology, prosthetic limbs can be customized to fit the specific needs of each patient, providing a more comfortable and functional fit. reducing or eliminating labor costs.

Robotics

The use of 3D printing in robotics has allowed for the creation of complex and precise parts that are difficult to manufacture using traditional methods. This has led to advancements in the field of robotics, including the development of more capable and versatile robots.

From manufacturing to space exploration, the possibilities for 3D printing in robotics are endless. With this technology, we can create robots that are more efficient and effective than ever before.

Not to mention this will help the automotive industry which has needed help in recent years.

Aerospace

3D printing technology has revolutionized the aerospace industry. With 3D printers, engineers can create intricate and complex parts that would be difficult or impossible to manufacture using traditional methods. 3D printed parts are also lighter and more durable than those made with traditional manufacturing techniques.

Healthcare

3D printers are revolutionizing the healthcare industry and not just for body parts. The technology is now being used to create prosthetic limbs, dental implants, surgical tools, and even human organs. 3D printing allows for customized solutions that can be tailored to each patient’s specific needs.

For example, a surgeon can use 3D printing to create a model of a patient’s organ before performing surgery, allowing for better precision and accuracy. Additionally, 3D printing can reduce costs and lead times associated with traditional manufacturing methods, making it an attractive option for healthcare providers across the globe.

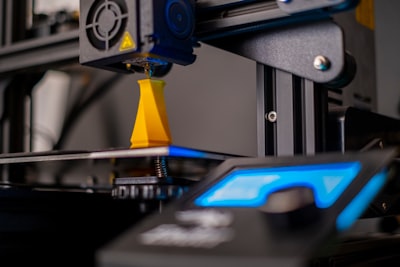

Fused deposition modeling

Fused deposition modeling (FDM) is one of the most common 3D printing technologies that uses a thermoplastic material to create objects by layering heated plastic in a specific pattern. FDM allows designers to create functional prototypes or end-use parts for a variety of applications including automotive, aerospace, and healthcare.

The technology is known for its high accuracy, speed, and ability to produce complex geometries. With FDM, it’s possible to create objects with different shapes and sizes, making it a versatile technology for many industries.

Metal Filament

One of the most exciting uses for 3D printers is the ability to print with metal filament. Metal filament allows for 3D printed objects to have a metallic finish and feel. This can be especially useful for creating jewelry, architectural models, and even automotive parts. This helps every additive manufacturing process including rapid prototyping, spare parts creation and molds.

Food

Another good example to use for 3D printers is in the food industry. Using edible materials, 3D printers can create intricate designs and shapes that would be difficult to achieve with traditional cooking methods. This technology has been used to create personalized chocolates, intricate cake decorations, and even entire meals.

In addition to its creative uses, 3D printing in the food industry also has practical applications such as creating custom nutrition plans for patients with dietary restrictions or allergies. As the technology continues to advance, we may soon see 3D printed food in our everyday lives.

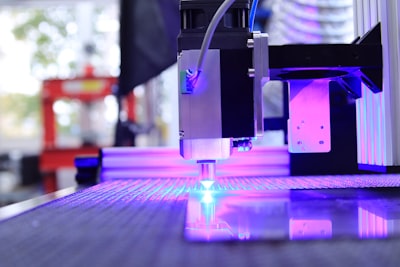

Flexible SLS 3D Printing Material

The advancement in 3D printing technology has led to the development of flexible SLS (Selective Laser Sintering) materials. These materials can be used for creating a wide range of products, from phone cases to prosthetic limbs. The flexibility of these materials allows for greater customization and comfort, making them a popular option in the consumer market.

Additionally, SLS printing can create complex geometries that would be difficult with traditional manufacturing techniques, allowing for more innovative and unique designs.

How is NASA using 3D printing?

NASA has been utilizing 3D printing technology to create tools and parts for the International Space Station (ISS). Due to the limitations of space travel, it is not practical to bring every tool or spare part needed for repairs or experiments. Instead, NASA is able to send 3D printers to the ISS and use them to create necessary items on-demand.

How can I use my 3d printer?

There are countless ways to use a 3D printer, and the possibilities are only limited by your imagination! Some ideas to get you started are: Create custom phone cases or other accessories or make personalized jewelry or keychains.

What are the pros and cons of 3D printing?

The potential for cost savings in manufacturing, and the more sustainable use of materials. On the other hand, the cons include limitations in material options, slower production times compared to traditional methods. You choose which is better.

Conclusion

The uses for 3D printers are truly endless. Whether you’re a fashion designer, a robotics enthusiast, or just someone who loves to tinker and create. There’s no denying that 3D cad software has opened up a world of possibilities. In the near future there will be many different types of items including those for dentistry printing work.

And also, the variety of materials that they get to use will be just as endless.

be sure to follow on Facebook, Pinterest, Twitter, Youtube, and Instagram.