Tips for 3D Printing

Tips for 3D Printing

To improve your 3D printing skills with Tips for 3D Printing. Start by calibrating your printer and ensuring proper bed leveling. Experiment with different print settings, such as layer height and print speed. Learn from online tutorials and forums on the internet, and practice regularly to gain experience and troubleshoot issues effectively.

Learn CAD and Create Basic, Useful Objects

Learning CAD (Computer-Aided Design) modeling software, such as printing software, is essential for anyone interested in 3D printing. With CAD software, you can design and create basic, useful objects that can be printed with a 3D printer. CAD allows you to bring your ideas to life by providing tools and features to create precise and detailed designs.

By learning CAD modeling software, you can unleash your creativity and explore the endless possibilities of 3D printing. Whether you’re a hobbyist or a professional, mastering CAD modeling software will open up a whole new world of possibilities in the realm of 3D printing.

Find and download free files.

When it comes to 3D printing, finding and downloading free files is a great tip for beginners. There are numerous websites and online platforms that offer a wide range of pre-designed 3D printable files, from simple objects to intricate models.

These files are ready to be downloaded and printed, saving you time and effort in designing your own models from scratch. Whether you’re looking for functional objects or decorative pieces, exploring these online resources can provide you with endless possibilities for your 3D printing projects.

Tips for 3D Printing

Stereolithography

Stereolithography is a popular 3D printing technique that uses a laser to solidify liquid resin, such as photopolymer, into intricate 3D shapes layer by layer. It offers several advantages over other 3D printing methods, such as high resolution and accuracy, smooth surface finish, and the ability to create complex geometries. However, there are some important tips to keep in mind when using stereolithography for your 3D printing projects.

From choosing the right resin and adjusting the print settings to post-processing techniques and handling safety precautions, this guide will provide you with valuable insights to maximize the potential of stereolithography in your 3D printing endeavors.

SLA printing tips

SLA (Stereolithography) printing is a popular 3D printing technology that uses liquid resin and ultraviolet (UV) light to create high-resolution prints. Here are some helpful tips for successful SLA printing:

1. Choose the right resin: There are different types of resins available, each with its own properties and applications. Consider factors such as flexibility, strength, and transparency when selecting the resin for your project. Additionally, make sure to choose a resin that is compatible with your build plate and provides adequate support material.

2. Fine-tune your support structures: SLA prints often require support structures to prevent warping or collapsing during the printing process. Take the time to optimize their placement and density to ensure successful printing and easy removal afterwards.

3. Experiment with print settings: Adjusting parameters such as layer height, exposure time, print speed, and slicers can greatly impact the quality of your SLA prints. Take the time to experiment and find the optimal settings for your specific project, depending on the type of printing you are doing.

4. Post-processing techniques: SLA prints may require upgrades and post-processing to remove any excess resin and achieve a smooth surface finish. Consider using methods such as washing, curing, sanding, and machining to refine your prints.

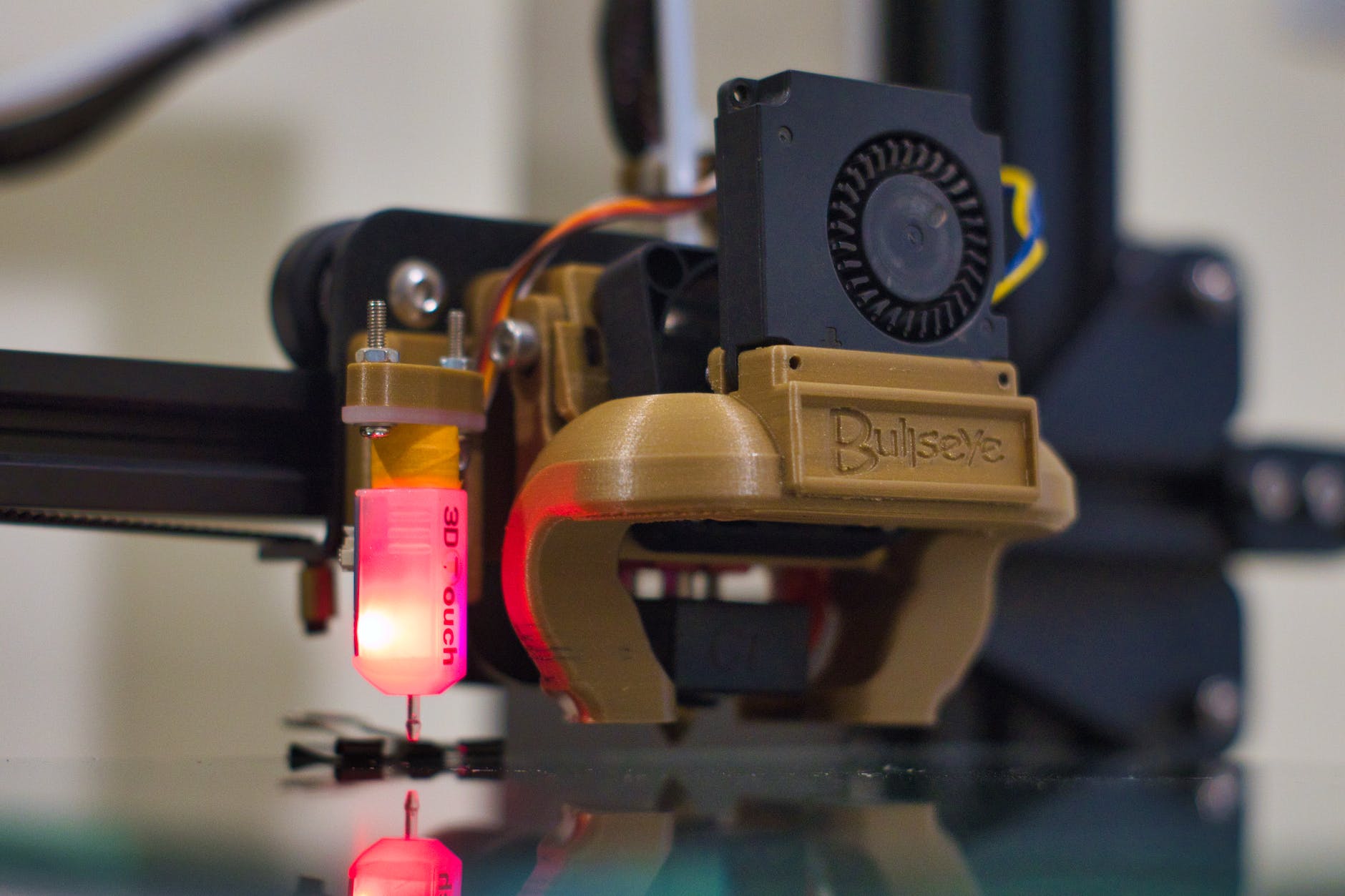

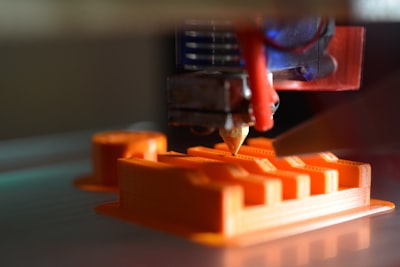

Extrusion / FDM / FFF

Extrusion, FDM (Fused Deposition Modeling), and FFF (Fused Filament Fabrication) are three common terms used in 3D printing, specifically referring to the process of material deposition. In this technique, a thermoplastic filament is heated until it becomes molten and then extruded through a nozzle in layers to create a three-dimensional object.

FDM is the most widely used 3D printing technology due to its affordability, versatility, and ease of use. It allows for the creation of complex geometries and functional prototypes. However, there are certain tips and considerations to keep in mind when using FDM printers to ensure optimal print quality and successful outcomes.

Use PLA Filament

One important tip for 3D printing is to use PLA filament for the best results. PLA (Polylactic Acid) is a popular and widely used filament material in 3D printing. It is derived from renewable resources such as corn starch or sugarcane and has several advantages.

PLA is easy to print with, has a low melting point, and produces minimal warping or shrinking during the printing process. It also tends to have a pleasant, slightly sweet smell compared to other filaments. Additionally, PLA is biodegradable and environmentally friendly, making it a great choice for sustainable 3D printing projects that require strong abs.

Grinding Filament

Grinding filament is a common issue that 3D printing enthusiasts may encounter, leading to printing issues. When the filament gets stuck or grinds, it can lead to failed prints and frustration. To prevent this, there are a few tips you can follow.

First, make sure your printer’s extruder is properly calibrated and the nozzle is clean. Additionally, check the tension on the filament spool to ensure it is not too tight or too loose. If grinding still occurs, try reducing the print speed or adjusting the temperature settings. Regularly inspecting and replacing worn-out nozzles or feeder gears can also help prevent filament grinding.

Change a Nozzle

Changing a nozzle is an important skill to have when it comes to 3D printing. Over time, nozzles can become clogged or worn out, affecting the quality of your prints. To ensure that your printer is working at its best, it’s important to perform regular calibration.

To change a nozzle, start by heating up the printer and removing any filament from the extruder. Use a wrench or pliers to unscrew the old nozzle, being careful not to damage the heating block. Once the old nozzle is removed, screw in the new nozzle and tighten it securely. Finally, test the printer with a small print to ensure that everything is working properly. By learning how to change a nozzle and perform calibration, you can maintain the performance and reliability of your 3D printer.

Inconsistent Extrusion

Inconsistent extrusion is a common issue in 3D printing that can result in poor print quality. This occurs when the filament is not consistently fed into the printer’s nozzle, leading to uneven layers and gaps in the printed object. To address this problem, it is important to check and properly adjust the extruder tension and temperature settings.

Additionally, ensuring that the filament is free from any obstructions or tangles can help maintain a smooth and consistent flow during the printing process. Using high-quality parts and regularly cleaning and maintaining the printer’s extruder mechanism can also prevent clogs and improve overall printing performance, ultimately increasing the success rate of your 3D prints.

Related Articles

- Best 3D printers

- 10 Best uses for 3D printers

- The 3D Printing Process

- Materials for 3D Printing

- Software 3D Printing

- Best 3D Printers for Beginners

How Much Does a 3D Printer Cost?

When it comes to 3D printing, one of the most common questions is, “How much does a 3D printer cost?” The cost of a 3D printer can vary greatly depending on several factors, such as the brand, model, and features.

Entry-level 3D printers can range from $200 to $500, while more advanced models can cost anywhere from $1,000 to $5,000 or more. It’s important to consider your budget and intended use for the printer when deciding which option is right for you. Additionally, keep in mind that there are additional costs associated with 3D printing, such as filament and maintenance.

What is the best way to learn about 3D printing?

The best way to learn about 3D printing is through a combination of online resources, tutorials, and hands-on experience. Start by researching reputable websites, joining forums or communities dedicated to 3D printing, and experimenting with different designs and materials using a 3D printer.

Conclusion

Tips for 3D Printing is an exciting and versatile technology that allows for the creation of unique and customized objects. By following these tips, such as adjusting extruder settings and maintaining the printer’s mechanism, you can ensure high-quality prints with minimal issues.

When considering purchasing a 3D printer, it’s important to factor in the cost of both the printer itself and additional materials and maintenance. Finally, the best way to learn about 3D printing is to utilize online resources, tutorials, and hands-on experience. Be sure to follow on Facebook, Instagram, and Twitter.